Mod. 910

INTEGRATED WITH TIG-DC INVERTER POWER SOURCE 200A

TECHNICAL FEATURES OF GENERATOR Mod. 910

Power: 6,0 KVA

Max load: 16 A max

Power factor: 0,99/86%

Current regulation range: 5 ÷ 180

Max current: 200 A (35%) / 140 A (100%)

Max no-load voltage: 90 V

Protection: IP 32

Supply voltage: 230 V (da -40% to + 15%)

Encumbrances WxHxL: 560 x 450 x 250 mm

Weight: 20 Kg approx

PROGRAMMER / GENERATOR complete with:

– 7 ”Touch Screen color graphic display, front rotary encoder for all functions

– 24 column plain paper impact printer

– Separate cooling unit with instrument for measuring temperature level and refrigerant liquid

– USB interface for LOG and programs transfer

– Front key for program modification disable

– Simplified programming by entering tube parameters

– Remote control for manual head movements with start/stop welding cycle control (opt.)

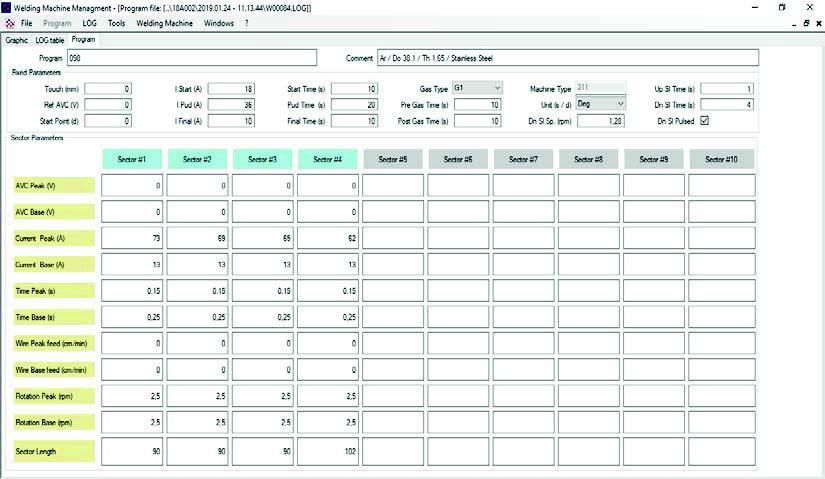

– “WMM” (Welding Machine Manager ) Windows program supplied with the system

– Connection via WiFi interface for Industry 4.0 compatibility

TECHNICAL SHEET MOD. 911

Capacity: 4,5 liters, stainless steel tank

SYSTEM EQUIPPED WITH TEMPERATURE AND REFRIGERANT FLOW CONTROL

Encumbrances WxHxL: 560 x 250 x 250 mm

Weight: 10 Kg approx

FORCED VENTILATION WITH INSIDE FAN

For more information

Contact us

– Welding programs management

– WPS definition

– Edit, modify, copy and print welding programs

– USB and WiFi interface

– Up to 255 programmers

– Easy to use

– Single program and welding Log

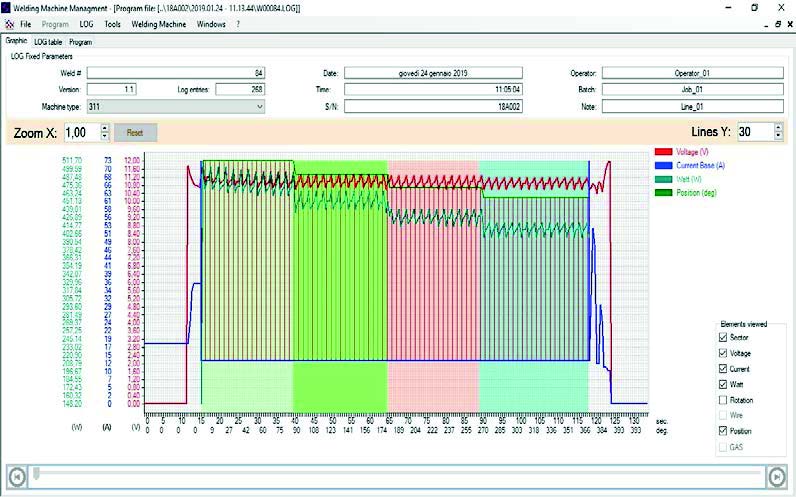

– Voltage, Current (Pk, Gnd), Welding power, Sectors, Machine rotation speed, Filler wire speed, Gas flow, machine position are displayed.

– Management Operator and Job for any single welding

– Welding data recorded in real time, displayed in text or graphic

– Real time machine status and errors management

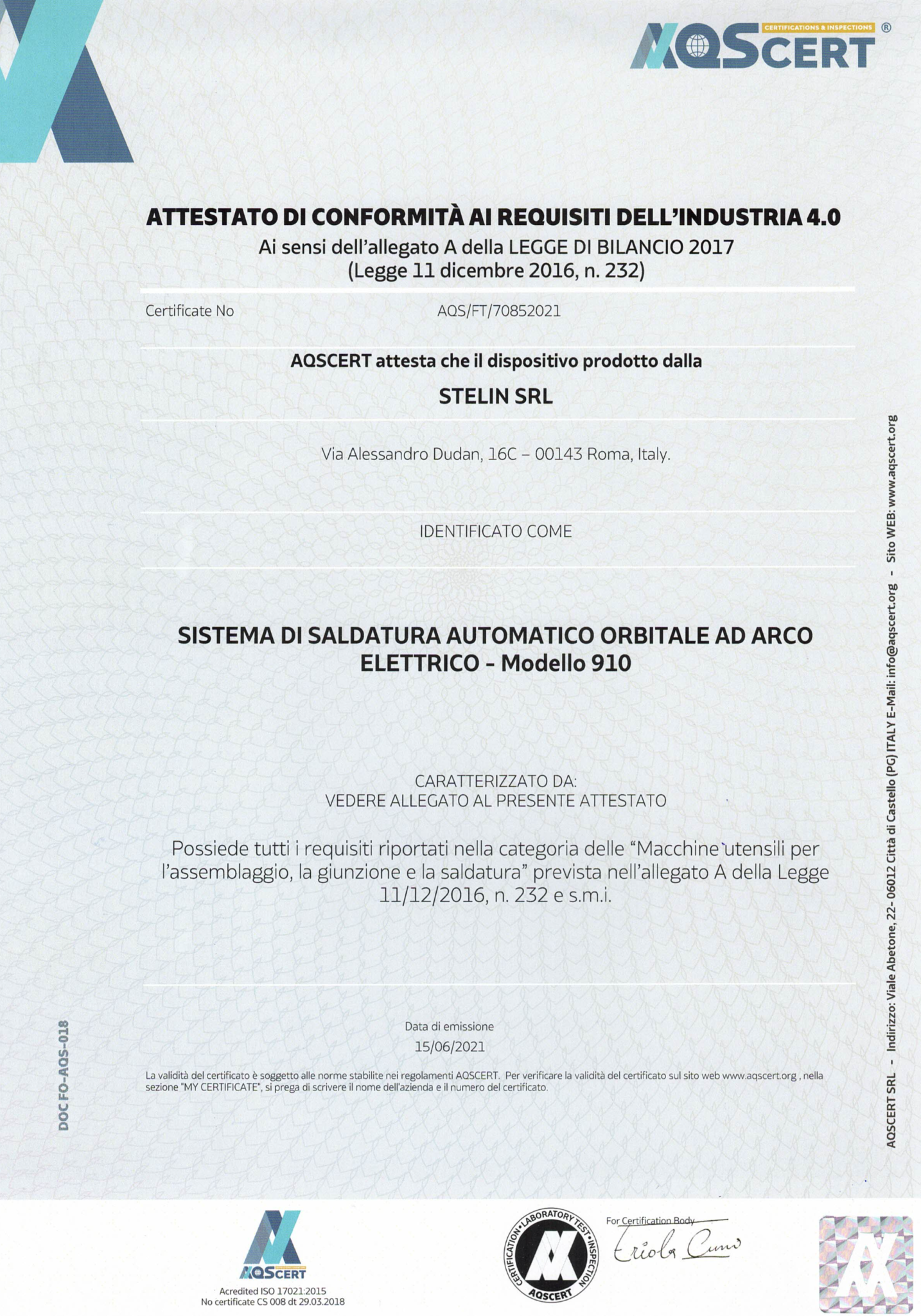

Stelin Industrial Systems, with a view to the continuous improvement of its products and the utmost attention and guarantee towards its customers, is pleased to announce the achievement of the certification of compliance with the requirements of the “Industry 4.0” directives of its programming system for Welding Orbital Mod. 910.

This important objective, in addition to representing the only equipment currently available on the market with this certification, is a guarantee and support tool for the end customer, in order not only to guarantee an increase in company competitiveness, but also ” obtaining the tax advantages provided for by current regulations.

Stelin Industrial Systems, always one step ahead to give the best customer service.

Our border is the world

OPERATING OFFICE

Via Alessandro Dudan n.16/c

00143 ROMA

ITALY

SHOWROOM – TEST AREA

EsseBi WELDING – Via Cà Magre, 23

37063 Isola della Scala (VR)

© 2023 Stelin S.r.l. All rights reserved. P. IVA 08540001008 Privacy Policy Cookie Policy powered by Web Agency