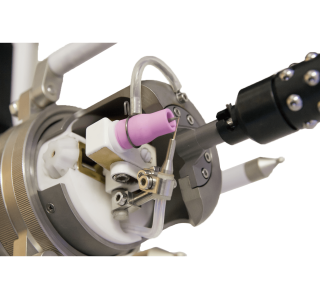

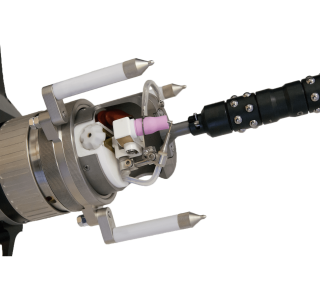

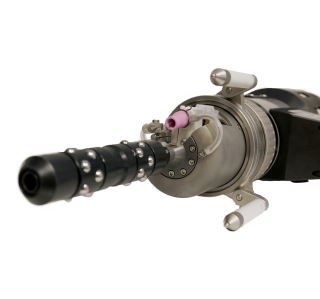

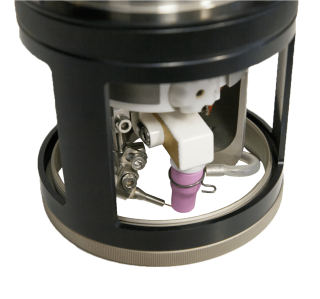

ORBITAL WELDING HEAD FOR TUBE TO TUBE-SHEET

Mod. 116

WELDING HEAD

Pre-heating of the tubesheet up to 200 C°

On request up to 400 C°

PRODUCT TECHNICAL SHEET

Welding procedure: TIG with or without filler wire

Welding position: Horizontal, vertical, inclined

Welding head position: Suspended by spring tool balancer

Torch inclination: ± 45°

Electrode diameter: 1 ÷ 3,2 mm

Welding diameter: 10 ÷ 80 mm max (electrode parallel to the tube axis)

Welding current: 200 A DC max pulsed / linear

Rotation speed: 0,10 ÷ 4,73 rpm (± 1%)

Torch centring: By mandrels and centring cartridges

Electrode-to-work distance adjust: By a micrometrical screw located on the machine body (total stroke 10 mm)

Filler wire feeding unit: Directly assembled on the machine body. The unit rotate with the torch.

Filler wire speed: 10 ÷ 200 cm/min (± 1%)

Filler wire spool: Standard, Midget type Ø 4” (about 100 mm)

Filler wire diameter: 0,6 ÷ 1,2 mm

Cooling head: Water for torch and body

Tube plate preheating: Up to 200°C. On request up to 400°C

Connecting cable: L = 8 m (4,100 Kg)

Machine weight: 7,600 Kg

Weight of filler wire unit: 2,270 Kg

Supply voltage: 24 V DC

For more information

Contact us

Our border is the world

OPERATING OFFICE

Via Alessandro Dudan n.16/c

00143 ROMA

ITALY

SHOWROOM – TEST AREA

EsseBi WELDING – Via Cà Magre, 23

37063 Isola della Scala (VR)

© 2023 Stelin S.r.l. All rights reserved. P. IVA 08540001008 Privacy Policy Cookie Policy powered by Web Agency