Automatic Orbital Welding

Specialists in the design, development, production and assistance for

AUTOMATIC ORBITAL WELDING SYSTEMS

AUTOMATIC ORBITAL WELDING SYSTEMS

Planning

We design and manufacture our products based on customer needs.

Development

The development of our products is guaranteed by continuous investments in new technologies to be applied.

Optimization

We optimize our production procedures thanks to continuous checks and tests to guarantee a reliable product.

Post sales assistance

The ongoing relationship with our customers allows us to guarantee a high-profile after-sales and assistance service.

what do we do

Products for orbital welding

Need more information?

Specialists in the Design, Development, Production and Assistance of

Systems for Automatic ORBITAL WELDING

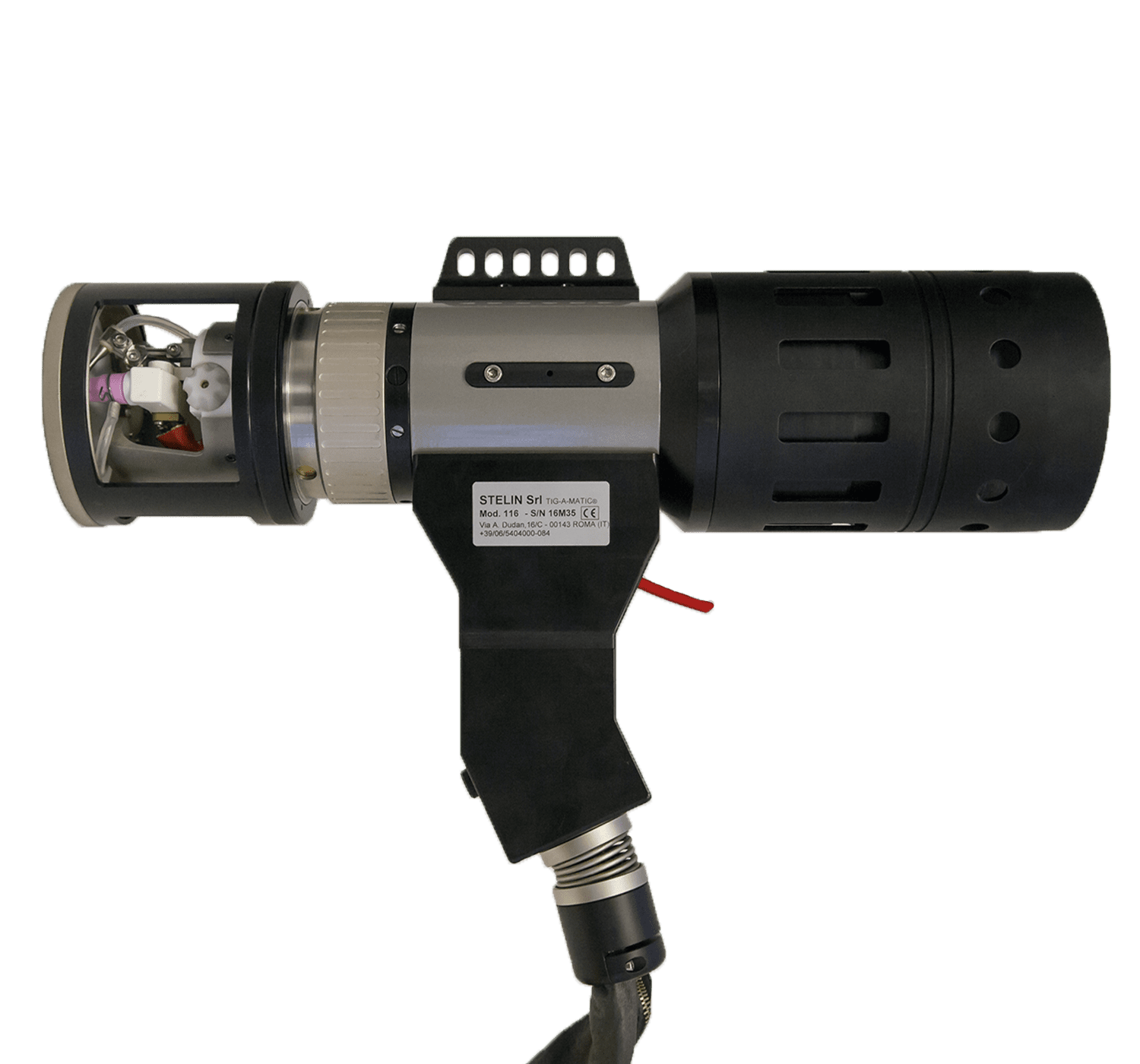

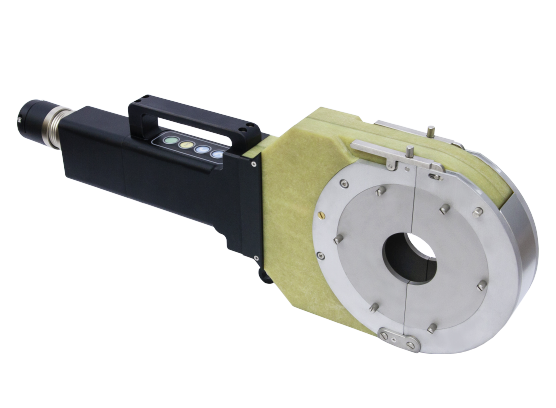

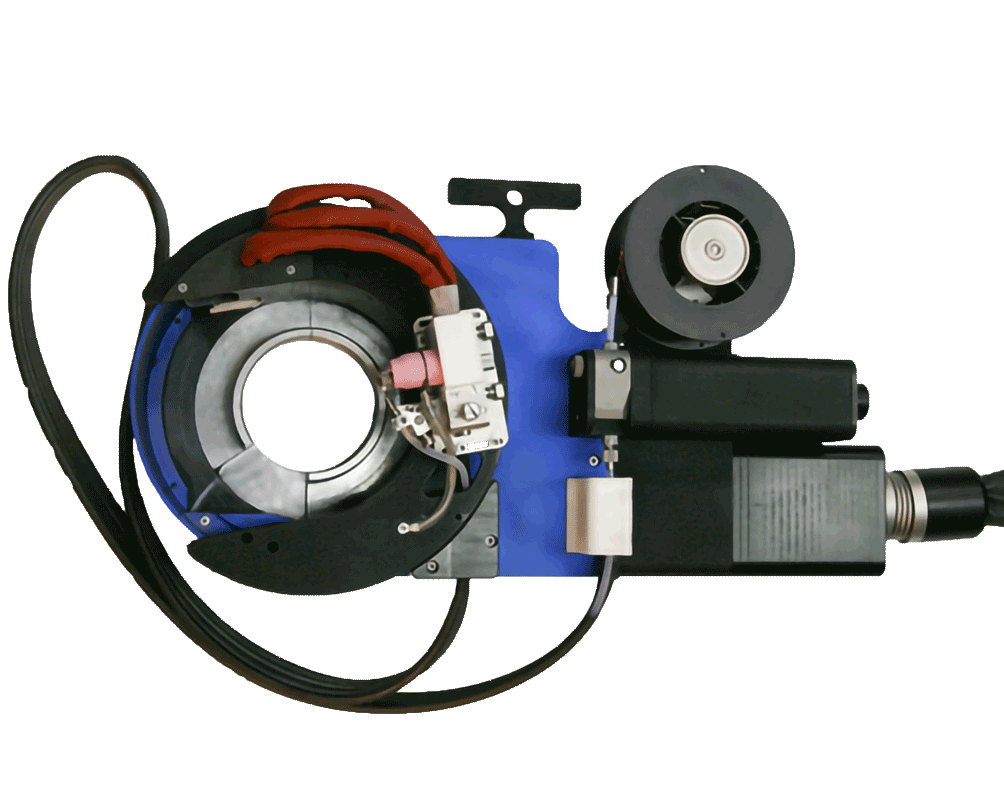

STELIN Srl prides itself on being the only Italian company to design and build automatic orbital welding systems.

For over 25 years distribuites its products under TIG-A-MATIC® brand which is known both in Europe and in the rest of the World.

All projects of orbital welding systems are based on a modular design, simply to use and easy to maintain.

STELIN

Develops TIG-A-MATIC® welding systems to cover all orbital welding applications, that for tube to tube-sheet and for tube to tube, and that for any kind of welding geometry.

Common objects of TIG-A-MATIC® products can be so resumed:

-

Reliability and repeatable of welding proceeds

-

Flexibility and adaptation to work on specific applications

-

High performances

In 2014, the STELIN Srl has obtained the Certification for its Quality Assurance System ISO 9001:2008.

All products have the CE mark and comply with the current European Directives.

Need more information?

What they say about us

Customer testimonials

International

Our border is the world

Where we are

OPERATING OFFICE

Via Alessandro Dudan n.16/c

00143 ROMA

ITALY

SHOWROOM – TEST AREA

EsseBi WELDING – Via Cà Magre, 23

37063 Isola della Scala (VR)

© 2023 Stelin S.r.l. All rights reserved. P. IVA 08540001008 Privacy Policy Cookie Policy powered by Web Agency